What about the specification and size of PPR pipe and fitting?

The specification of PPR pipes and fittings is a seemingly simple problem, but not everyone can make it clear. Because there are different types of pipes in the water pipe industry, the characteristics of such pipes are different, so the meaning of specification parameters describing them is also different. The specification parameters of PPR water pipe are mainly the pipe diameter specification and wall thickness, so let’s talk about it in detail.

PPR pipe diameter specification

First of all, three concepts should be clarified: nominal outer diameter Φ, nominal diameter DN, and English unit.

The nominal outer diameter of the pipe is the outer diameter of the pipe. It is usually marked with DN in lowercase, that is, the number after Φ marked on the pipe.

The nominal diameter DN is the average outer diameter of the pipe, which is generally a round integer and a reference value, which is different from the actual pipe size.

British units are worth what people often call four, six and one inch.

The wall thickness of the metal pipe is generally thin, so the average diameter of the outer diameter and the inner diameter is almost equal to the outer diameter, i.e. DN = Φ. However, for PPR pipes, due to the thick wall thickness, the difference between the nominal outer diameter DN and the actual outer diameter of the pipe is still large, so it needs to be distinguished.

In PPR water pipe, there are the following relations among the British unit, nominal diameter and actual outer diameter:

In the domestic piping, the common outer diameter specifications of PPR water pipe are 20mm, 25mm and 32mm.

PPR Tube series: S

For the wall thickness property of PPR pipe, there are two parameters, pipe series s is one of them.

By definition, pipe series s is a dimensionless number related to the nominal outer diameter and nominal wall thickness, which is used to guide the selection of pipe specifications. It is a set of round integers after calculation.

In GB / T 18742.2-2017 polypropylene piping system for hot and cold water part 2: pipes, the specific specification parameters of ppr pipe and fitting series s are as follows, as shown in the table below:

When the nominal outer diameter of PPR pipe is fixed, the larger the pipe series s is, the thinner the wall thickness of water pipe is, and the smaller the pipe series s is, the thicker the wall thickness of water pipe is.

Standard size ratio: SDR

Standard size ratio is another parameter related to the wall thickness of PPR pipes. According to the SDR value of standard size ratio, PPR pipes are divided into five series: sdr11, SDR9, sdr7.4, sdr6 and sDR5.

The standard size ratio SDR is the ratio of the nominal outer diameter of PPR pipe to the nominal wall thickness. The relationship between SDR and PPR tube series s is: SDR = 2S + 1.

The same as the pipe series, when the nominal outer diameter of PPR pipe must be, the larger the standard size is than SDR, the thinner the wall thickness of water pipe, and the smaller the standard size is than SDR, the thicker the wall thickness of water pipe.

Specification of PPR pipe fittings

The nominal outer diameter DN of PPR pipe fittings is always consistent with the nominal outer diameter DN of PPR pipes connected with it, and is often marked on the PPR pipe fittings.

The wall thickness of PPR pipe fittings shall not be less than that of PPR pipes of the same PPR pipe series s. Most enterprises only have a series of PPR pipe fittings of the highest standard S2, which are all applicable to hot and cold water.

For pipe fittings with thread, i.e. threaded parts, the specification of thread is commonly used in two types, 1 / 2 and 3 / 4, i.e. the difference between 4 points and 6 points. The corresponding nominal diameter of thread is 15mm and 20mm respectively.

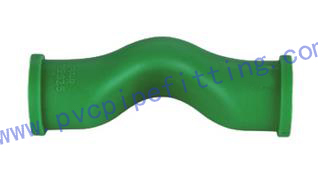

The nominal outer diameter of PPR fitting 45 ° elbow is 25 mm, that is to say, the pipe with the nominal outer diameter of 25 mm is connected.

Shijiazhuang xingyin import and export trade Co., Ltd. is the PPR pipe fittings manufacturer,PPR pipe fittings supplier. We are one of the best factories in China. Our products are of reliable quality and can be used by families and wholesalers. We can provide a variety of color PPR pipe fittings. We can provide national standard goods, non-national standard goods, according to the requirements of the production of PPR pipe fittings.

http://www.pvcpipefitting.com/what-about-the-specification-and-size-of-ppr-pipe-and-fitting/

http://www.pvcpipefitting.com/what-about-the-specification-and-size-of-ppr-pipe-and-fitting/