How to choose and buy PPR pipe fittings?

1. See the material

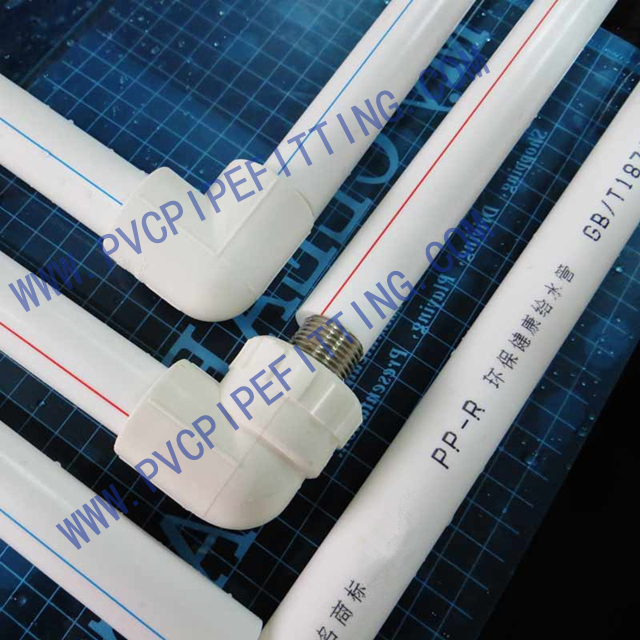

Good PPR pipe fittings are made of excellent polypropylene materials. The color of the pipe fittings is pure, the feel is fine, and the surface is smooth and flat.

The poor PPR pipe fittings are usually produced with low-cost recycled materials. The color of the pipe fittings is dark, the hand feel is rough, and even there are defects such as black lines and bubbles. This kind of pipe fittings not only buries potential safety hazards to the domestic piping system, but also affects the health of domestic drinking water. Consumers must polish their eyes.

We can check its light transmittance. The high-quality PPR pipe has good light transmittance, which can be raised in the sun to observe its light transmittance

2. Look at technology

Good PPR pipe fittings have advanced and exquisite production technology. In the production process, they are extruded by a single machine and molded once, ensuring the quality of the pipe fittings. The copper inserts in the pipe fittings will also be treated with special technology to ensure the quality and the health of consumers’ drinking water.

The copper insert of poor PPR pipe fittings is made of copper or copper alloy without surface treatment. It will not only oxidize and rust, but also accelerate the oxidation and degradation of PPR pipe fittings, ultimately reduce the service life of the pipe and affect the safety of the overall water pipe.

Good PPR pipe fittings are made of excellent polypropylene materials. The color of the pipe fittings is pure, the feel is fine, and the surface is smooth and flat.

The poor PPR pipe fittings are usually produced with low-cost recycled materials. The color of the pipe fittings is dark, the hand feel is rough, and even there are defects such as black lines and bubbles. This kind of pipe fittings not only buries potential safety hazards to the domestic piping system, but also affects the health of domestic drinking water. Consumers must polish their eyes.

We can check its light transmittance. The high-quality PPR pipe has good light transmittance, which can be raised in the sun to observe its light transmittance

2. Look at technology

Good PPR pipe fittings have advanced and exquisite production technology. In the production process, they are extruded by a single machine and molded once, ensuring the quality of the pipe fittings. The copper inserts in the pipe fittings will also be treated with special technology to ensure the quality and the health of consumers’ drinking water.

The copper insert of poor PPR pipe fittings is made of copper or copper alloy without surface treatment. It will not only oxidize and rust, but also accelerate the oxidation and degradation of PPR pipe fittings, ultimately reduce the service life of the pipe and affect the safety of the overall water pipe.

When we buy, we can first smell the irritant smell of PPR pipes and pipe fittings with our nose. Good quality plastic water pipes should be odorless, because polypropylene is non-toxic and tasteless. Consumers can take a small part of the sample of the plastic water pipe and immerse it in high-temperature hot water. The good quality plastic water pipe will still maintain the original hardness, while the poor quality water pipe will soften at about 60 ℃. When purchasing pipe fittings, first check whether the color and glossiness are uniform, whether the wall thickness of pipe fittings is uniform, and whether the pipe wall is smooth. For pipe fittings with screw thread, pay attention to whether the thread is evenly distributed.

4. When purchasing PPR pipe fittings, the pressure bearing degree should be selected according to the current tap water pressure, generally 1.6Mpa, 2.0MPa, and the pipe wall is 2.3, 2.8, 3.5 and 4.4mm thick. It’s not that the higher the pressure is, the greater the thickness is, but it’s enough. Because the tap water pressure we know at present is the pressure value at the factory. If it really flows to your home, the pressure will be greatly reduced. We often see the water supply pipe break on the road, but generally it is not caused by too much pressure, but by vehicle pressure loss and aging of water pipe. Generally speaking, 2.3 or 2.8 pipe wall, 1.6Mpa pressure is enough for domestic use.

PPR pipe joints should not be too many: the inner diameter of the pipe is smaller when there are more heads, which increases the resistance of water, resulting in the reduction of water flow per unit time, and the joints are too many, which is also prone to poor connection. Therefore, if the water pipe can go straight, it can go straight. If it can go straight, it can go straight. If it can not be assured, it can do closed water test. If the pressure is 0.6MPa for 24 hours, it is normal if the pressure does not drop.

5 select brands.

Shijiazhuang xingyin import and export trade Co., Ltd. is the PPR pipe fittings manufacturer,PPR pipe fittings supplier. We are one of the best factories in China. Our products are of reliable quality and can be used by families and wholesalers. We can provide a variety of color PPR pipe fittings. We can provide national standard goods, non-national standard goods, according to the requirements of the production of PPR pipe fittings.

Shijiazhuang xingyin import and export trade Co., Ltd. is the PPR pipe fittings manufacturer,PPR pipe fittings supplier. We are one of the best factories in China. Our products are of reliable quality and can be used by families and wholesalers. We can provide a variety of color PPR pipe fittings. We can provide national standard goods, non-national standard goods, according to the requirements of the production of PPR pipe fittings.

没有评论:

发表评论