https://www.pvcpipefitting.com/the-difference-between-pvc-u-pipe-pvc-o-pipe-pvc-m-pipe/

The difference between PVC-U PIPE, PVC-O PIPE, PVC-M pipe

PVC-U PIPE, PVC-O PIPE, and PVC-M pipes are three different pipes. Although they are both made of PVC, the performance and uses of the three pipes are different. The pvc pipe manufacturer will introduce PVC-U, What is the difference between the three pipes of PVC-O and PVC-M pipes.

Rigid polyvinyl chloride pipe, referred to as PVC-U pipe, as a new type of building material, has attracted more and more attention and attention. It is light in weight, smooth, beautiful, small in water resistance, flexible in assembly, time-saving and labor-saving in installation, and is very popular among design, construction units and users. Therefore, the use of PVC-U pipes to replace traditional cast iron drainage pipes is becoming an irreversible trend and is quickly becoming popular throughout the country. At present, most of the pipes used in tap water transportation, domestic sewage discharge, and construction wires are rigid PVC pipes.

Compared with steel, iron, concrete and ceramic pipes, PVC-U PVC pipe has the following advantages:

Light weight, the relative density of the rigid PVC pipe is 1.43, which is only 1/6 of the weight of steel of the same size. -1/3.

Easy to connect and easy to install. Because the PVC-U pipe is light in weight, easy to connect, and has a certain toughness, it is easy to install. Compared with other pipes, the more complicated the pipeline system is, the more prominent the advantages of the PVC-U pipe are.

Good corrosion resistance and flame retardant properties.

Good electrical insulation performance, its volume resistance is about 1 × 10 ~ 3 × 10, and the breakdown voltage is 23 ~ 28Kv/mm.

Frictional resistance is small. The fluid velocity in the pipe is about 30% higher than that of the steel pipe, and there is less scaling and no rust. The flow rate and flow rate can remain unchanged for long-term transportation of water and other fluids; while the iron pipe will rust and scale, and after several years of use Both the flow rate and flow in the tube are reduced.

The thermal conductivity is small, the weather resistance is good, and the heat insulation performance is good.

Coloring is convenient, no paint is required, and it is easy to make pipes with various marking colors. The energy consumption in production is low, which is only 18.3% of that of cast iron pipes.

Long service life, the service life of traditional pipes is 20-30 years, and the service life of PVC-U pipes is not less than 50 years under rated temperature and pressure, and the maintenance cost is only 30% of cast iron pipes or concrete pipes.

PVC-U: Non-plastic PVC pipe is the most common type of pipe in the pipeline processing industry. The molecular structure of PVC pipes is a randomly arranged long chain structure, which is the most common in PVC pipes. Generally speaking, PVC molecules do not show obvious directionality, that is to say, its axial and radial strengths are consistent. Although CHINA PVC pipeline system has formed a huge scale with an annual output of more than 1 million tons, it has always stayed within the scope of traditional PVC-U. Many enterprises do not understand the trend and progress of PVC pipeline technology innovation in the world, because of technological progress. Slowness restricts further promotion and application.

PVC-O: PVC-O biaxially oriented pipe fittings, the extruded pipes are preheated for a second time and then oriented by axial and radial stretching to obtain pipes with higher strength and higher toughness. The molecular chain of the material forms an interwoven network-like lamellar structure through the biaxial orientation process. The thickness of this high-strength material can be thinner than ordinary PVC pipes, which not only reduces the production cost, but also makes the pipes have considerable toughness. Therefore, PVC-O pipes are not used as gravity pipes, and are mainly used in water supply pipes, mine pipes, pipes for trenchless laying and repairing, gas pipes, etc., especially in harsh environments with strict safety requirements and corrosive underground environments.

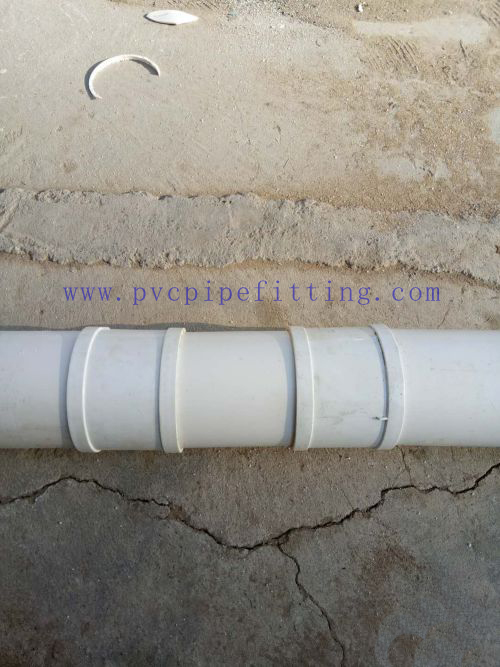

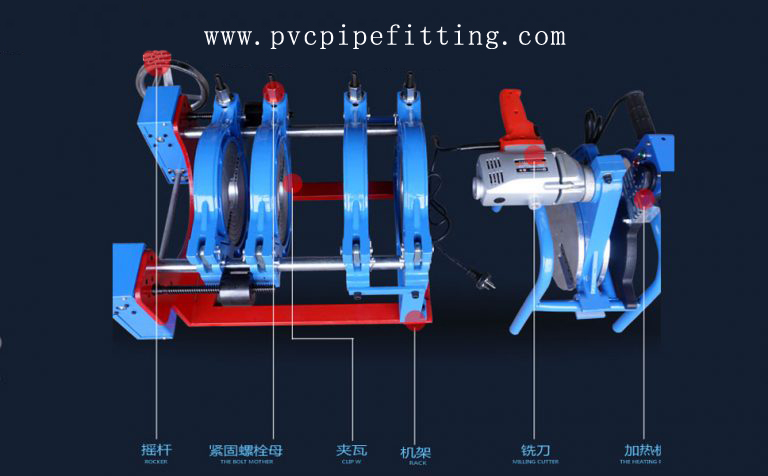

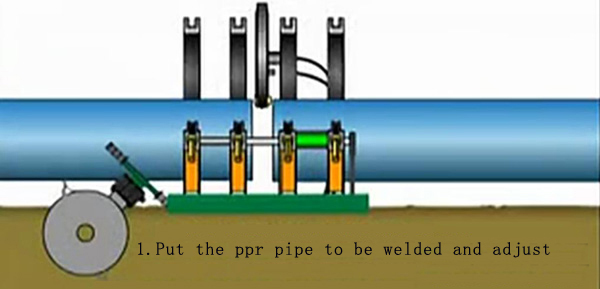

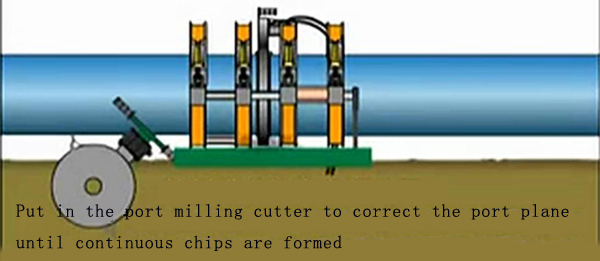

PVC-M: Modified PVC pipes can be obtained by incorporating additives or “impact modifiers” to increase the strength of the material. While maintaining the elastic modulus of PVC-U pipe, PVC-M pipe allows PVC pipe to be bent, folded, and even butt welded to a certain extent, and its toughness is between PVC-U and PE. Its good toughness improves the water hammer resistance and point load capacity of the pipe, and the wall thickness is 30% smaller than the corresponding PVC-U pipe, which is convenient for handling and transportation, and improves the safety of pipeline operation. The United Kingdom, Australia, South Africa and other countries already have national standards, and a large number of pipes are used in mines with harsh working conditions, requiring high strength and high toughness, and pipes for trenchless laying and repairing.