Drinking water pipes are totally basic facilities for any sanitation system in homes, premises, or offices. Choosing the right type of material for your drinking water connections is a key factor for its proper functioning. Therefore, in this post, we will teach you the types of drinking water pipes and which is the best option.

They are used in all types of installations, there is even some heat-resistant plastic pipe that can be used in heating installations (hot water), although it is not highly recommended, better copper.

PVC pipes and CPVC pipes are probably the most widely used pipes today.

CPVC is a more rigid version of PVC.

Polyethylene (PE) would follow in the ranking of most used pipes.

hdpe water supply pipe

The main difference compared to PVC is that PE is more flexible.

Plastic pipes called PER (cross-linked polyethylene) are also widely used since it is an extremely robust and durable plastic.

They are stronger than normal PVC pipes and contain more chlorine, making them safer and less likely to affect water quality.

We are going to list some of its advantages:

They are resistant to corrosion.

The plastic tubes are flexible and easy to fit.

They are cheaper than other materials.

The systems for joining the plastic pipes make the installation of water easy and time-consuming.

Cleaning plastic water pipes is also straightforward because most of the time it is just unscrewing. Plastic is also suitable for all kinds of water hardness.

In addition, the plastic water pipes remain rust-free.

The smooth surface of the tubes prevents the accumulation of lime and dirt. They are also resistant to acids (water alkalinity) and lime.

Copper Water Pipes

Copper water pipes are particularly strong, robust, and durable, but they are more expensive than plastic ones.

It is used in gas, heating, and plumbing installations.

Copper pipe welding requires some manual experience, so installation is more expensive and should only be done by professionals (plumbers)

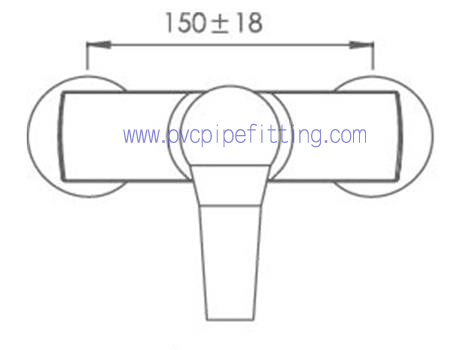

The components that connect pipe sections to each other today are often press fittings (straights, deviations, or branches)

In the past, pipes used to be bent at a high cost, but today, thanks to pressure fittings, they offer a cost-effective alternative in money and time.

However, copper water pipes are not recommended if the pH value of the drinking water is too low (less than 7), that is, acidic water as it carries health risks.

Therefore, regular inspection of these types of water pipes is particularly important.

Galvanized Steel Pipes

The great disadvantage of steel is its low resistance to corrosion since in contact with air and humidity it rusts easily and can be completely destroyed.

Thus, steel pipes need surface protection, which is usually galvanized.

Galvanizing is coating one metal with another.

This is the best type of pipe for your hot water supply.

They also tend to last longer than all other types of pipes.

Galvanized steel is a traditional pipe material.

Modern versions of galvanized pipes are considered a relatively safe medium for drinking water.

However, there are potential health problems if the water supply is corrosive due to low pH.

It is mainly used for outdoor pipes, as these pipes are usually larger in diameter.

Compared with traditional cast iron pipes, galvanized steel pipes, cement pipes, and other pipes, PPR pipes have the advantages of energy saving, material saving, environmental protection, lightweight, high strength, corrosion resistance, smooth inner walls, simple construction and maintenance, and long service life. It is widely used in construction, municipal, industrial, and agricultural fields such as building water supply and drainage, urban and rural water supply and drainage, urban gas, electric power and optical cable sheath, industrial fluid transportation, agricultural irrigation, etc.

Drinking water pipes and fittings must be made of materials resistant to materials, gases, and metals normally dissolved in water and therefore resistant to corrosion.

The material used in each case depends mainly on the hardness of the water.

Very hard water produces limestone, very soft water causes corrosion.

The basic rule is that the materials must not impermissibly impair the quality of drinking water in terms of its food quality.

copper and PVC pipes are the most used for drinking water.

PVC pipe used only for cold water, and CPVC pipe used for cold and hot water have been around for years, and both are approved for use with potable water.

But the truth, neither of them can be described as environmentally friendly from a production or recycling point of view.

Copper pipes are the best option for water pipes.

They are durable and do not leach chemicals into drinking water.

However, copper pipes are generally more expensive and the intensive process of extraction and manufacture of copper presents some environmental imbalances.

Also, if the water has a pH value of less than 7, you will need to install a system to balance the acidity of the water, so that it does not corrode the copper.