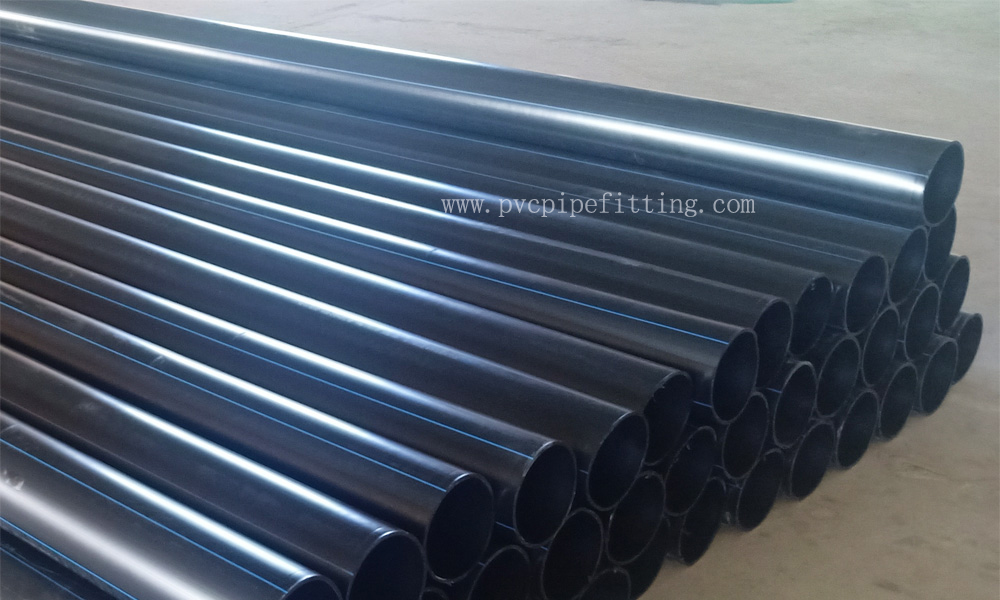

What is hdpe water supply pipe

HDPE water supply pipes have been greatly developed and improved in terms of design theory and construction technology in construction, occupying a very important position in the field of building water supply pipe engineering, and have begun to gradually replace the more used PVC- U water supply pipe, PP-R pipe, aluminum-plastic composite pipe, steel-plastic composite pipe, etc. The rapid development of hdpe water supply pipes is mainly due to the use of advanced production technology and technology in the production of hdpe water supply pipes, which are formed by hot extrusion, with strong corrosion resistance, smooth inner wall, low flow resistance and high strength , Good toughness, light weight and other characteristics.

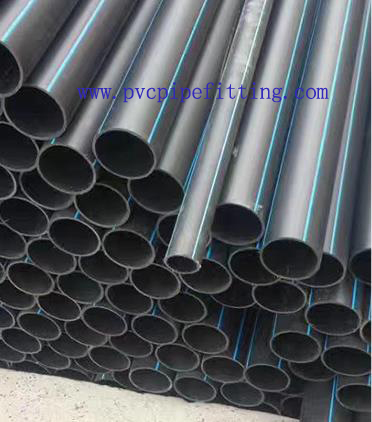

Application field of HDPE water supply pipe

HDPE water supply pipe is mainly used for: municipal engineering water supply system, building indoor water supply system, outdoor buried water supply system and residential area, factory area buried water supply system, old pipeline repair, water treatment engineering piping system, gardens, irrigation and other fields Industrial water pipes, etc.

But it should be noted that HDPE water supply pipes cannot be used for hot water pipes.

Application characteristics of HDPE water supply pipe

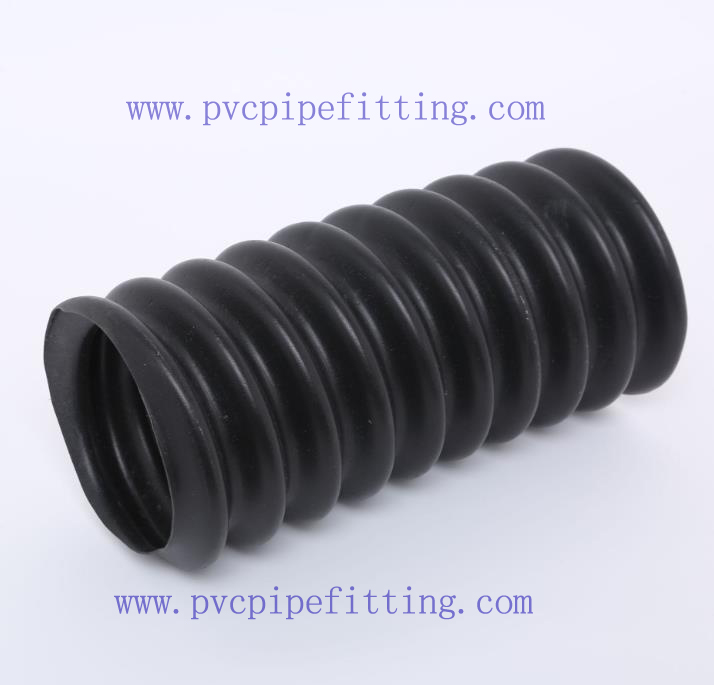

1. It is easy to butt welding and electrofusion welding to form a closed anti-seepage system. When laying along the trench, it can reduce the amount of trench excavation earthwork and reduce the number of accessories.

2. Lightweight and easy to install and handle;

3. With strong wear resistance and good hydraulic performance, no external protection is needed for buried pipelines. It can be applied to earthquake and soil settlement areas in mining areas, and it can also be laid at the bottom of rivers by the sinking method.

4. Chemical resistance, internal, external, and microbial corrosion resistance, strong corrosion resistance, and good sanitary performance. It is suitable for transporting acidic and alkaline substances, sewage, natural gas, coal gas, and other substances;

5. Good environmental adaptability and frost resistance. Can be used for indoor and outdoor water supply pipelines.

6. Long service life.

7. Easy to recycle.

We are a professional HPDE pipes and fittings manufacturer ,We have advanced production equipment and excellent product quality, welcome to consult.

How to produce PE water supply pipe