pvc pipe joint type

There are many types of PVC pipe joints. They connect every part of the piping system together so that the piping helps to transport water from the water supply system to the sink. Without pipe connectors, the entire city’s pipe system would be unusable.

What is a PVC connector?

pvc pipe joint

Pvc joint is to connect PVC piping system together to change the direction of water flow.

It is mainly divided into two aspects,Plumbing connectors PVC joint, and Furniture grade connectors PVC joint.

Plumbing connectors

Plumbing connectors are often used in pipeline drainage systems, house water supply systems, and sewer systems. They connect every corner of the city and are used in people’s houses, office buildings, and urban plumbing systems.

Plumbing connectors are not beautiful, but very practical.

If you are a wholesaler of PVC pipes or a wholesaler of PVC pipe fittings, you can buy them in our factory.

If you are an individual, you can buy them from our worldwide PVC pipe wholesalers or PVC pipe fitting wholesalers.

Furniture grade connectors

Furniture grade connectors show you the other functions of PVC pipe fittings. They are not limited to the basic idea of connectors. They are often used in supermarkets, shopping malls, and some special customized products.

Furniture-grade connectors can be connected with PVC pipes to make shopping racks, display racks, or other commodities. Similarly, if you are a wholesaler of PVC pipes or a wholesaler of PVC pipe fittings, you can buy them in our factory.

If you are an individual, you can buy them from our worldwide PVC pipe wholesalers or PVC pipe fitting wholesalers.

Whether it is Plumbing connectors or Furniture grade connectors, you can DIY PVC products.

Most Common Types of PVC Pipe Connectors

Just like there are several types of PVC pipes, there are many types of PVC pipe connectors.

- Adapters

- Bushings

- Caps and plugs

- Couplings

- Elbows

- Flanges

- Nipples

- Tees

- Crosses

- Saddle Tees

- Unions

- 3 way elbow

- 4 way elbow

- 5 way elbow

Adapters

The adapter is generally a threaded joint, and the adapter for garden hoses is unique,garden hose adapters provide an easy way to connect your home garden hose to a PVC pipe line. We carry a full selection of durable fittings for connecting to male and female hose ends to suit your unique needs.

Adapters come in most standard materials, including brass, copper, malleable, ABS, PVC, and steel.

Bushing

Bushings help you join pipes that have different sizes.

Bushing is divided into socket type and thread type.People make bushings from all sorts of piping materials, such as ABS, brass, copper, malleable, stainless steel, and PVC.

What is PVC bushing,This article can let you know more about it.

Caps and plugs

pvc fitting end cap for water supply has a socket opening for connecting to a pvc pipe or fitting, and is suitable for closing or terminating the end of a pipe or fitting.

Plugs have the same purpose, but you put them inside the fitting. They are threaded, so you can continue using the same pipe.

Plug is used to plug off a fitting in PVC systems. Plug is only designed to work with threaded fittings.Plug is made with a threaded end so that they will work with any fitting in the PVC system. plugs are pressure tested to meet all industry standard and can handle heat up to 140 degrees Fahrenheit.

Other than PVC, caps, and plugs are available in brass, copper, ABS, malleable, and steel.

Coupling

A coupling extends the pipe’s run.Coupling is divided into normal connection and Compression connection. Coupling can connect two PVC pipes of different sizes.

Couplings usually have female threads, but sometimes they can be unthreaded. You can take unthreaded pipes and either glue them or solder them with copper.

Apart from PVC, they come in ABS, copper, brass, malleable, and steel.

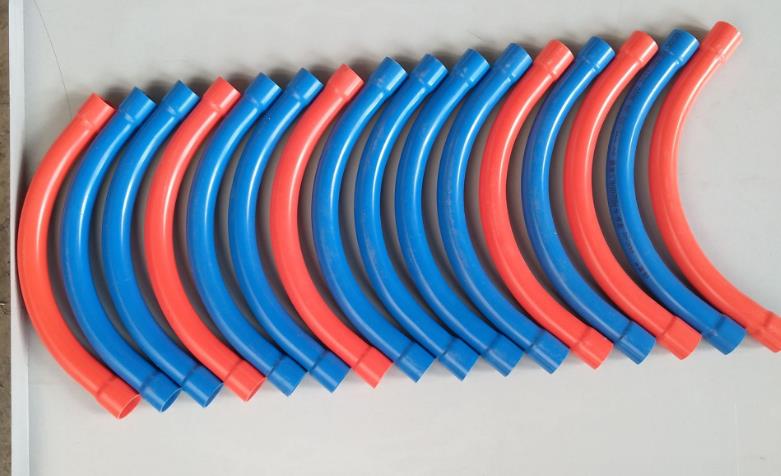

Elbow

The elbow is a joint that connects two PVC pipes and changes the direction of liquid flow. They are usually 45-degree elbows and 90-degree elbows. Of course, there is also a reducing elbow, which is used to connect two different size PVC pipes. Elbows with sockets also have threaded elbows. Divided into internal thread elbow, external thread elbow.

what is pvc elbow? This article can let you know more about it.

Elbows are one of the most crucial connectors in most plumbing projects. They come in PVC, but also in brass, copper, ABS, steel, and malleable.

Flanges

Flanges connect pipes. This is a great idea in case fixing PVC leaks is necessary. Pipes that you use with flanges end up either welded or threaded to the flanges.

Then, you seal them together with bolts. Professionals typically use flanges in industrial applications, especially when there is high pressure involved.

People use them for residential pump systems, as well, usually in the bathroom. These are the connectors that mount the toilet to the floor and extend to the drain.

Flanges come in PVC, copper, brass, and malleable. PVC flanges are the ones that you can find in toilets.

Nipples

Nipples look like short pipes that remind of stubs. They have male threads on both ends. Nipples connect two different straight pipe runs. Short nipples have a unique look, as they have threads from one end all the way to the other one. In other words, the threading goes throughout the length of the pipe. This helps them ensure very tight connections.

Nipples come in brass, copper, steel, malleable, and, of course, PVC.

Tees

Tees resemble the shape of a Latin letter “T.” They help you connect three or more pipes to ensure good water flow.

Essentially, it looks like a fairly long coupling that has an outlet on one side. This outlet comes at a 90-degree angle from the body of the connector. Its size depends on the size of the pipe.

The side outlet is usually referred to as the ‘top,’ and the straight-through part of the fitting is the ‘run.’ If the tee’s run is smaller than the top, this is called a ‘bull head’ connector.

Tees come in PVC, ABS, CPVC, brass, steel, and copper.

Crosses

Crosses are essentially tees with two tops. With them, you can connect four PVC pipes.

They are more limited compared to tees, and they come in less materials. Because of this, many professionals opt to use several tees instead of a cross connector.

Other than PVC, crosses come in malleable and brass.

Saddle tees

If you need to add a pipe or tee to an existing pipe quickly, saddle tees are the way to go. You can also find them under the name ‘snap-tee.’ They are a great way to add a new pipeline without cutting an existing PVC pipe. Commonly, people use saddle tees on irrigation systems. This way, you will easily add another sprinkler line. To complete this task, you need to take a saddle tee and glue it to the pipe. After everything is set, you have to drill another hole, and everything is good to go.

Saddle tees come in PVC only.

Unions

Unions are more or less the same as couplings. If couplings are inconvenient or impractical, professionals use unions. Unsoldered couplings require you to thread pipes into them.

Unions, opposite to that, have their own nut that creates a seal that connects two pipes. For example, this is a great choice if you have two fixed pipes that you can’t thread into couplings.

This way, any future repairs will be much easier and straightforward. There are even dielectric unions that professionals use to join pipes made from different metal materials.

This is enabled thanks to their anti-corrosion properties. However, unions come with a few downsides. The main one is that you can’t use them with LP or natural gas.

Unions come in PVC, brass, CPVC, malleable, brass, and steel.

3 way elbow、4 way elbow、5 way elbow

This is a special connection tool. We have two products: furniture level and pipe level.

Our customers buy these three products for display racks, clothes racks, and the like.

They can connect PVC pipes in three directions or multiple directions

Are there different standards for PVC pipe joints?

There are many standards for PVC pipe joints produced by our factory, Schedule 40 PVC fitting, Schedule 80 PVC fitting,BSP, ASTM, GB, and so on.

It can meet the needs of different countries and regions.

Are there different sizes of PVC pipe joints?

Just like there are many standards for PVC pipe joints, there are also many sizes. This can be done so that you can better connect to PVC tubes of different sizes.

Different standard PVC pipe joints have different size standards.

A good side of PVC connectors is that you can use them with pipes made from non-PVC materials. Suppose this is the case; the nominal size is not as important anymore.

Now you don’t need to look at the outside diameter of everything. Instead, the pipe’s outer diameter needs to be compatible with the inner diameter or the connector.

However, a 2″ pipe of copper, for example, might not fit a 2″ PVC pipe connector.

A nominal size only matters if both the pipe and the connector are PVC.

This is why it’s important to know all existing types of PVC pipe connectors. Different connectors are made in different ways.

Understanding them and understanding how manufacturers make them is crucial to finding a pipe that fits.

We are a professional manufacturer of PVC joints. We can wholesale PVC pipes, wholesale PVC pipe fittings, wholesale PVC joints.

If you have any needs, please consult me.

https://www.pvcpipefitting.com/pvc-pipe-joint-type/