Doing projects with PVC pipe will often require the pipe to be cut. One of the advantages of PVC is that it can be cut easily, with a wide variety of tools, which makes the job relatively simple. You don’t need a complicated setup or fancy tools to cut PVC pipe. A variety of different tools can be used, including hacksaws, pipe cutters, and a miter saw to get the job done right.

1 Cutting pvc pipe with a hacksaw

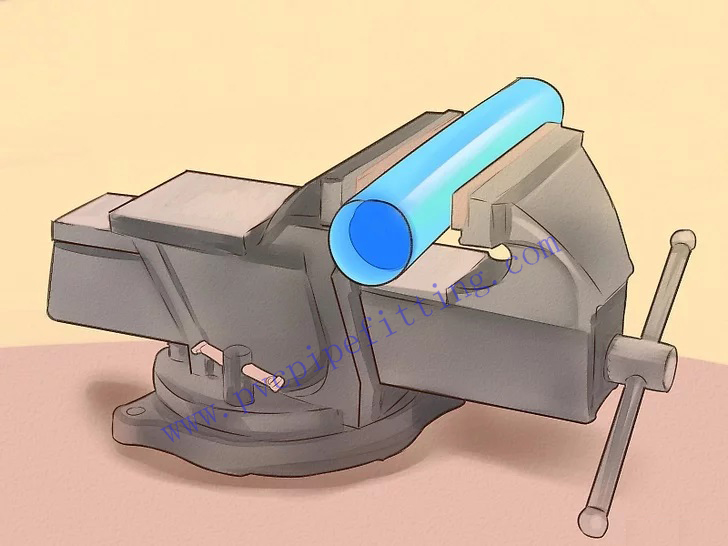

(1) Clamp the pvc pipe in a vise. The most basic and useful tool for cutting pipes, PVC or other materials is the hacksaw. Even so, it is very important to use a vise to prevent it from moving and the risk of cutting yourself with a movement of the blade. Be extremely careful and take the necessary precautions when holding the tube.

You can use another type of work handle in place of the vise to hold the pvc pipe on your workbench. Use what you have available.

Hold it a few inches from the cutout to give yourself plenty of clearance. If possible, hold on to both sides of the cut, but with a handle, a few inches from the intended location will be secure enough.

(2) Mark the PVC pipe where you are going to cut. Use a permanent marker to clearly indicate the part of the tube that you will cut. Don’t worry if the mark stays, as you can clean it later with a little rubbing alcohol if you want a good finish.

(3)Insert the saw teeth into the pvc pipe. Place the hacksaw on the mark and hold it firmly by the grip. Next, use your other hand to press down on the top of the saw, sinking the teeth into the tube. It is advisable to start at the correct point, as this will not start with messy cuts.

(4)Saw the pvc pipe firmly. Start sawing, making sure to watch carefully as you cut and not let the saw drift from the mark you originally made. Saw fast enough to cut without stopping, but not so slowly that your teeth jump off the mark. You should be able to cut the PVC pipe relatively quickly.

2 Use a pipe cutter to cut pvc pipe

(1)Get a plastic pipe cutter. There are two types of PVC pipe cutters: scissor style and ratchet style. Scissor style cutters are ideal for 1.3cm to 2.5cm PVC pipe, but are sometimes too difficult to use on larger pipes. Instead, use a ratcheting plastic pipe cutter, ideal for larger pipes and effective for smaller ones as well. It is much more secure and reliable.

The force required to use the scissor-style cutter is sometimes a bit extreme, and it is easier to use a saw of any type. Investing in a ratchet mower will make the job much easier.

(2)Place the pvc pipe in the lower half-moon shaped part of the cutter. Tube cutters have a rounded, open edge for placing the tube, and a blade that extends as you press the trigger on the handle. Mark the place where you want to cut, mount the pvc pipe in the mouth of the cutter and start cutting.

(3)Fit the blade against the tube. Press the trigger on the clipper handle to extend the blade and cut the tube in half. Use your other hand to hold the tube firmly when cutting. It shouldn’t be a very difficult job.

3.Cut pvc pipe with a miter saw

(1)Consider using a miter box to make more specific cuts. You can use a miter saw on PVC projects that require a lot of specific and detailed cuts. Use a blade with the appropriate number of teeth for the cut and available saws. When in doubt, use a standard 10 tooth per inch (TPI) wood saw, which is included in most miter saws. However, it will depend on the particular brand and style of saw you have.

(2)Place the PVC pipe under the sheet where you need to cut. Miter boxes are the easiest thing to use in the world, as you have cut lines indicated on the box. You cannot fail.

(3)Secure the tube with a working clamp. Activate the blade and lower it at a fairly low speed. Once you’ve made the cut, you can easily repeat the process, making any additional cuts needed.

4 If you don’t have the tools above, you can use white paper and a hacksaw

First prepare white paper and sawtooth, then draw mark on PVC pipe. Wrap the PVC pipe with white paper to make the PVC pipe more straight. Please see the video for details.

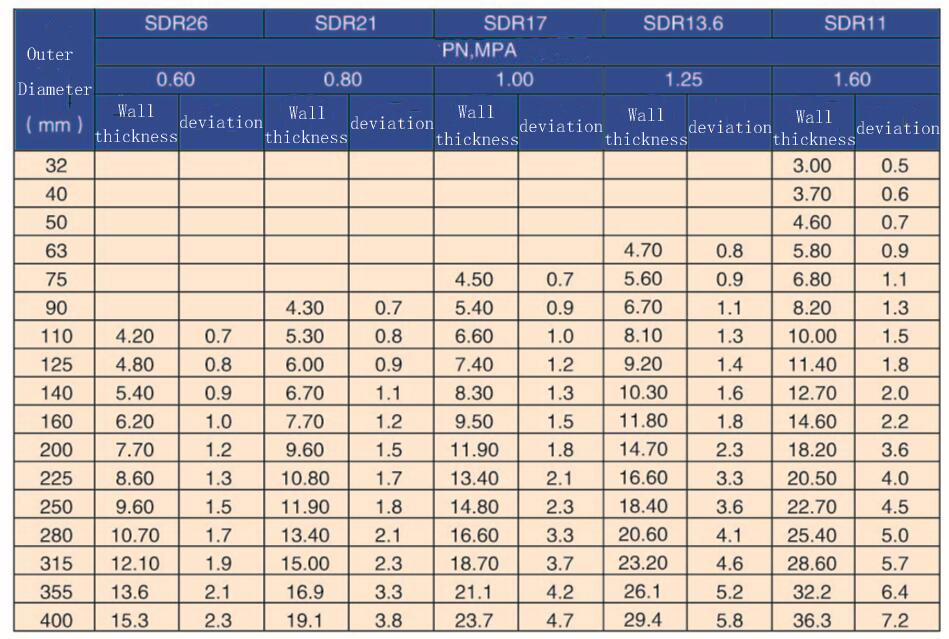

Pvc pipe and fitting size chart

Tips

Regular wood saws have teeth too far apart and will not cut PVC properly.

Cutting PVC pipe with any of the following tools is not recommended:

Table Saw: Never use a table saw to cut PVC pipe. This material is curved. The surface of a table saw is flat and often smooth to allow wood to pass through easily. Pushing a PVC pipe into a table saw can cause it to slip and cause serious injury to the user.

Band saw: A band saw blade moves too slowly and unless you use a fine tooth blade it can cling to the inside diameter of the tube, causing cracks and chips that are a potential hazard.

Warnings

Always wear eye protection when cutting PVC pipe. If the tube is old and brittle, it may crack and fragments may fly out.

https://www.pvcpipefitting.com/how-to-cut-pvc-pipe-straight/