Pvc pipe and fitting size chart description

Pvc pipe and fitting size chart includes the national standards, sizes, Imperial and Metric, symbols, etc

The meaning of De, DN, D, Φ

The diameter of PVC pipe and fitting can be divided into outer diameter (De), inner diameter (D), and nominal diameter (DN).

1. DN refers to the nominal diameter of the pipe, which is the average of the outer diameter and the inner diameter. The value of DN=the value of De-0.5*tube wall thickness. Note: This is neither the outer diameter nor the inner diameter. Water and gas transportation steel pipes (galvanized steel pipes or non-galvanized steel pipes), cast iron pipes, steel-plastic composite pipes, and polyvinyl chloride (PVC) pipes shall be marked with a nominal diameter “DN” (such as DN15, DN50).

2, De mainly refers to the outer diameter of the pipe. The outer diameter of PPR, PE pipe, and polypropylene pipe is generally marked with De, and all need to be marked in the form of outer diameter * wall thickness, for example, De25×3.

3, D generally refers to the inner diameter of the pipe.

4, Φ represents the diameter of an ordinary circle; it can also represent the outer diameter of the pipe, but in this case, it should be multiplied by the wall thickness. For example, Φ25×3, which means a pipe with an outer diameter of 25mm and a wall thickness of 3mm. For seamless steel pipes or non-ferrous metal pipes, “outer diameter × wall thickness” should be marked. For example, ф108×4, ф can be omitted. Some steel pipe standards in China, ISO, and Japan use wall thickness dimensions to represent the steel pipe wall thickness series. The expression method for this kind of steel pipe specifications is pipe outer diameter×wall thickness. For example, ф60.5×3.8.

The range of De, DN, and ф

1. De — outer diameter of PPR, PE, and PP pipes;

2. DN — nominal diameter of PVC pipe, cast iron pipe, steel plastic composite pipe, and galvanized steel pipe;

3. ф — seamless steel pipe or non-ferrous metal pipe shall be marked with “outer diameter × wall thickness”, such as ф 108×4.

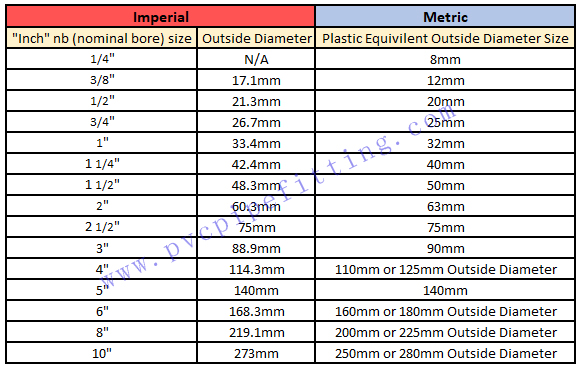

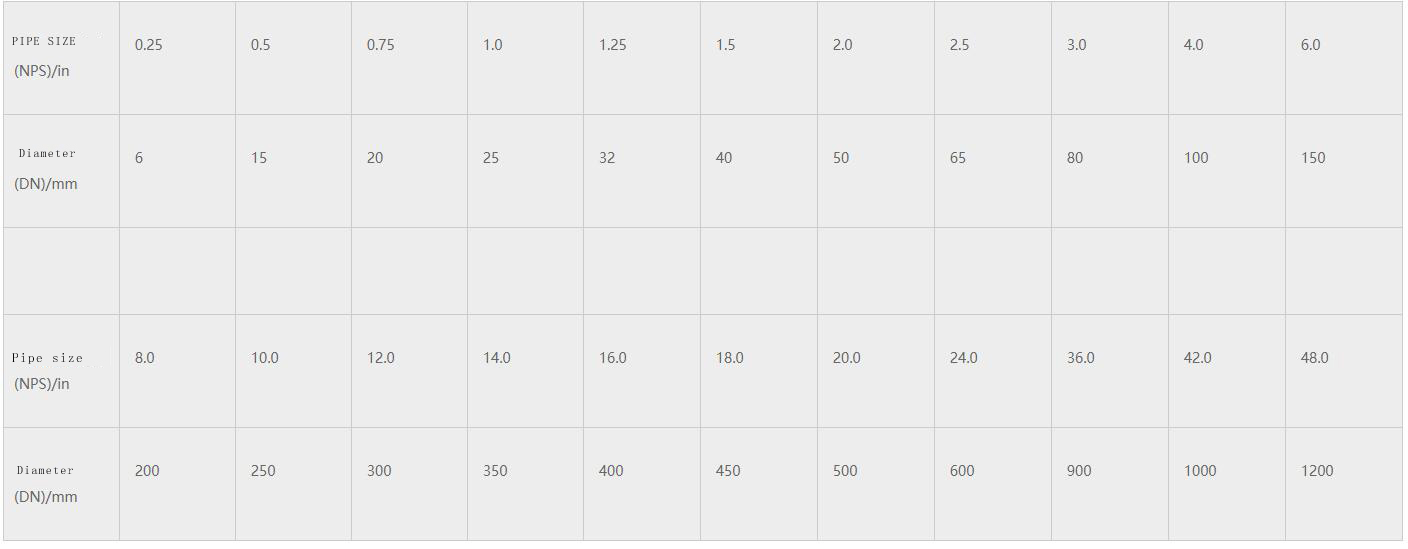

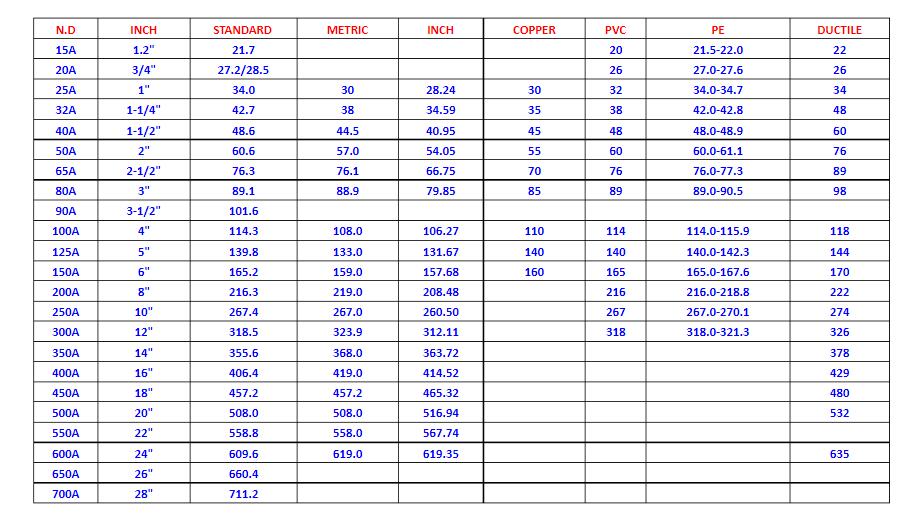

Pvc pipe and fitting size (Imperial and Metric Pipe Sizes comparison chart below)

Inch or mm: where did the confusion come from?

Tubes whose diameter is defined by inches (1-, 2-) and/or fractions of inches (1-, 1′-1), a generally accepted standard for water and gas supply.

The PVC pipes and fitting used for gas or water networks are usually measured in inches and not in millimeters. The diameter of the tube inch is 33,5 mm (see table), but the size of the inch in the SI system is 24,4 mm. The problem is that the size of the tubes is determined by the internal diameter and not by the outer diameter.

Measure the 1-diameter (how to measure the tubes is described below) and you will have a value equal to 33,5 mm, which obviously contradicts the classic linear conversion graph.

Normally, installing tubes in inches does not cause problems. But during its substitution by plastic, copper, or stainless steel, a problem arises- the one-inch indicated value does not match its actual value. Normally, this incompatibility is disconcerting, but if you look more deeply at the processes that occur in the tube, everything will fall into place.

The main point is that during the creation of the water flow, the main role is given to the internal diameter, not to the outer diameter, and so they use it as a designation. But the discrepancy with the usual rating system still remains, as for a regular tube the internal diameter is 27,1 mm, and for a reinforced tube- 25,5 mm. The latter is not far from equal that an inch is equal to 25.4, but not yet.

The fact is that the tubes are indicated by a nominal diameter, which is rounded to a standard value (conditional passage Dy).

Suppose the external diameter of the tube is 159 mm with a 7-mm wall thickness; in this case, the next exact diameter, which can be calculated by the formula D u003d 159 -7* 2u003d 145 mm, will be the exact internal diameter. With a 5-millimeter wall thickness, the diameter will be 149 mm. But in the first and second cases, the conditional pass will be the same and it will be 150-millimeter.

Both Imperial and Metric pressure pipe and fitting product quality are exactly the same.

Imperial is also known as the inch, and the inch is the unit of length. 1 inch = 2.53999918 cm (CM). The inch is used in the United Kingdom, the United States and other countries also use it.

Metric is also know as the MM,This size is widely used in Europe, Asia, China, and other countries.

For example, the DN25 (25mm, the same below) PVC water pipe and fitting is the British 1″ water pipe, which is also the previous 8-point water pipe.

The DN15 PVC water pipe and fitting is the British 1/2″ water pipe, which is also the previous 4-division water pipe.

For example, the DN20 PVC water pipe and fitting is the British 3/4″ water pipe, which is also the previous 6-point water pipe.

The relationship between outer diameter and DN, NB is as follows:

International pipe size comparison table

We’ve clearly defined this by listing both the Metric and Imperial sizes in our plastic pipe fittings catalog and on our website.

What Plastic do we offer?

we supply pvc pipe and fitting,cpvc pipe and fitting,ppr pipe and fitting,ips pipe and fitting,pvc rain gutter and so on.

What PVC do we offer?

Our PVC pipes and fittings are of excellent quality.

• Pipes

• Fittings

• Ball Valves

• Flanges

• Accessories